NOTE: The Fanuc Custom Macro A & B option may have to be purchased from Fanuc. NOTE: Additional Fanuc M-codes are specific to the machine builder and can be added as needed. Retract to R Plane or Feed per Revolution - Lathe Retract to Initial Plane or Feed per Minute - Lathe

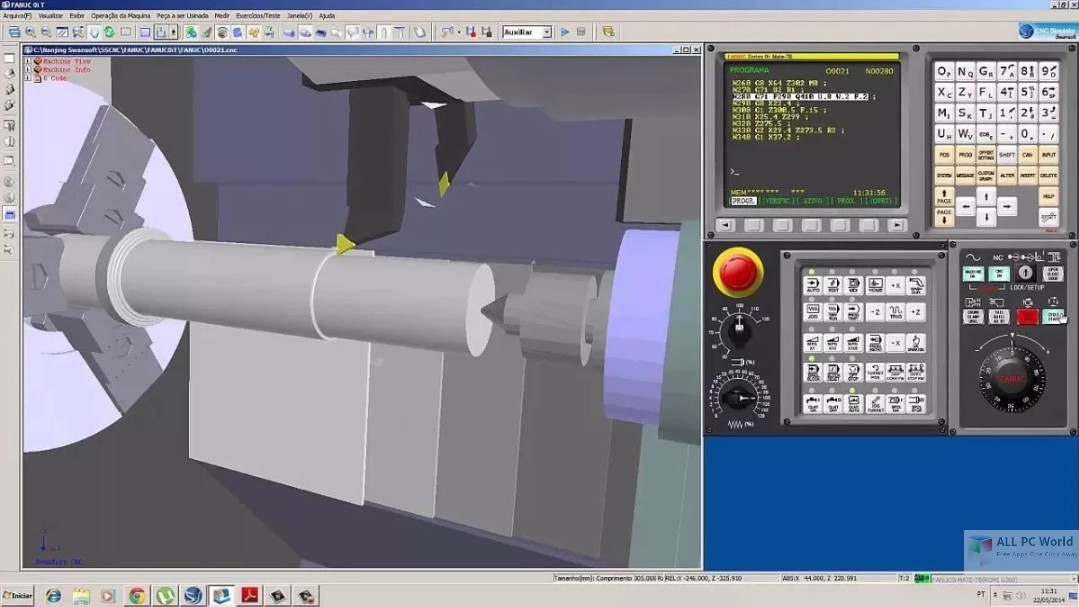

Hole Cycle - Mill or Groove Cycle - Lathe Supported Fanuc G-codes G-codeĬancel Scaling - Mill or Set Absolute Zero - Lathe Support for specific Fanuc G-codes and M-codes can be adjusted within every Predator Reverse Post Processor. Not all Fanuc G-codes are available for all Fanuc models and M-codes will vary with each machine builder. FANUC 0iF platform, the simulator will allow you at power on to switch between milling and turningconfigurations to teach programming, navigation and operation. Predator Virtual CNC includes support for all major Fanuc G-codes and M-codes standard. The FANUC CNC simulator is a perfect addition to the classroom and an essential component to gainmaximum exposure to FANUC CNC controls when actual machine time is limited. Within Predator Virtual CNC, maximize the performance and capabilities of each Fanuc CNC model and ensure that the proper part gets machined each time. Predator Virtual CNC provides comprehensive G-code based 3D CNC verification and machine simulation support for all Fanuc CNC models. Converts from raster to vector and refines architect, mechanical, tech drawing, maps, math graphs, graphics for books.Predator Virtual CNC™ for Fanuc CNCs 3D Machine Simulation, verification and backplotting for 2-5 Axis Fanuc CNC based Mills, Lathes, Mill/Turns, Lasers, Waterjets and Routers Fanuc CNC support with Predator Virtual CNC Software Free Cnc Programming Software Fanuc Windows 10 Fanuc Simulator Free Download Software development kit for CAD/CAM/ GIS and graphic software developers. The idea of the new CncSimulator is to provide the machining industry with a contemporary competent Fanuc-like CNC ISO simulator. Free Cnc Programming Software Fanuc Posted: admin On.For example, the formats of the Fanuc, Mitsubishi. It could convert the post-processed files made by the CAM software of Duct into different formats of header and footer for CNC Machine. It is the ideal tool for workshops wanting to test their code. The program supports 2-4 axis machines such as Milling machines, Turning machines, Laser Cutters, Plasma Cutters, Water Jet, 3D Printers, Plotters, and more. The CNC Header & Footer Convert is a free and beta software. CNC Simulator Pro is a Windows application used to simulate CNC programs before running them on an actual machine.

The realistic simulation software can be operated now as 5-axis and 3-axis mills or a 2-axis lathe. FANUC’s CNC Machining Simulation for Workforce Development offers virtual training on FANUC controls operation, part programming and more. FANUC has the CNC software you need! Whether you are trying to make data-driven decisions using machine tool info or creating a better part program - we can help you with that! Contact CNC Software Sales Machine Tool Data Software Connectivity Software Programming & Simulation Software.

0 kommentar(er)

0 kommentar(er)